How Do DC Photovoltaic Fuses Ensure Safety in High - Voltage PV Systems?

In today’s world, where clean energy is becoming increasingly important, high - voltage photovoltaic (PV) systems are playing a huge role in generating solar power. But with high voltage comes higher risks, like electrical fires and equipment damage. That’s where DC photovoltaic fuses step in as the safety heroes of these systems. Let’s take a closer look at how they work to keep everything safe.

1. Stopping Overcurrents: Protecting Against Sudden Surges

How It All Begins

Think of a PV system as a busy electrical highway. Sometimes, something unexpected happens on this highway, like a short - circuit. This can occur due to damaged wires, perhaps from a tree branch falling on them during a storm, or a faulty component inside the system. When a short - circuit happens, it’s like a traffic jam turning into a chaotic free - for - all, and the current in the system suddenly shoots up way beyond normal levels.

The Fuse’s Superpower

DC photovoltaic fuses are like the strict traffic cops of this electrical highway. Each fuse has a specific limit, called the rated current, that it can handle. When the current flowing through it exceeds this limit, the fuse element, which is made of a special metal that melts easily, starts to heat up. As the heat builds, the metal melts, creating a break in the circuit. This stops the excessive current from reaching important parts of the system, such as the inverters that convert the power and the charge controllers that manage it. By doing this, the fuse prevents these parts from overheating and potentially catching fire.

A Real - Life Example

Imagine a small rooftop PV system. One day, after a heavy rainstorm, a loose wire touches another wire, causing a short - circuit. The current in that part of the system suddenly increases. But thanks to the DC photovoltaic fuse installed there, the fuse element melts within seconds, cutting off the faulty circuit and protecting the rest of the system from damage.

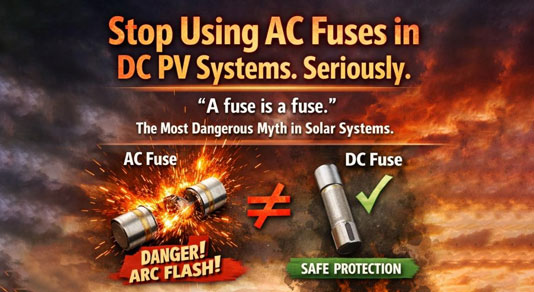

2. Tackling Arc - Faults: Preventing Electrical Fires

The Dangerous Arcs

Arc - faults are another serious problem in high - voltage DC PV systems. Picture two conductors in the system that are supposed to be separated but somehow, due to a loose connection over time or after a fuse blows, an electric arc forms between them. This arc is like a super - hot, invisible flame, reaching temperatures as high as 3,000 - 4,000 degrees Celsius. Any flammable material nearby, like the insulation around wires, can quickly catch fire, putting the whole system and even the surrounding area at risk.

Fuses to the Rescue

DC photovoltaic fuses are designed with special features to deal with these dangerous arcs. Many fuses have housings filled with ceramic or glass materials. When an arc forms, these materials act like heat sponges, absorbing the intense heat from the arc. This reduces the temperature and pressure of the arc, making it easier to extinguish. Additionally, the internal design of the fuse disrupts the path of the arc, preventing it from coming back and ensuring the circuit is safely shut down.

3. Isolating Faults: Making Troubleshooting Easier

How PV Systems Are Connected

Large - scale PV installations are like a big puzzle, with many pieces (PV panels) connected in series and parallel to form strings. Each string is responsible for generating a part of the total power. But if there’s a problem in one string, it could affect the whole system if not dealt with quickly.

Fuses as Problem Solvers

That’s where the DC fuses for each string come in. When a fault, such as an overcurrent or an arc - fault, occurs in a particular string, the fuse for that string blows. This acts like closing a faulty section of a road, isolating the problem string from the rest of the system. For the maintenance team, this makes their job much easier. Instead of having to search through the entire complex system, they can simply look for the blown fuse and focus on fixing the corresponding string, reducing the time the system is down.

4. Handling High Voltage: Built to Last

The Tough Environment

High - voltage PV systems operate in a challenging electrical environment, with voltages that can reach hundreds or even thousands of volts. At these high levels, there’s a lot of stress on all the components, including the fuses. The high voltage can cause the insulation materials around the fuses to break down, leading to current leakage, or it can damage the fuse terminals, which are used to make electrical connections.

The Fuse’s Design

DC photovoltaic fuses are made with strong and reliable materials. The insulation around the fuse is carefully chosen to withstand high voltages without breaking down. The terminals are designed to make secure connections that can handle the high electrical stress. This way, the fuses can keep working properly over a long period, providing continuous protection for the PV system.

In conclusion, DC photovoltaic fuses are essential for keeping high - voltage PV systems safe. Whether it’s stopping overcurrents, dealing with arc - faults, isolating problems, or handling high voltage, these fuses work hard to protect the system, prevent fires, and keep everyone safe. As we continue to rely more on solar energy, the importance of these safety devices will only grow.