gPV vs gG Fuse Classes: Engineering Guide for Photovoltaic and Industrial Protection

By Aite Fuse

1. Introduction – Understanding Fuse Classification in Modern Power Systems

As renewable energy and electrification accelerate globally, ensuring safe and efficient circuit protection has become a central engineering concern. From photovoltaic power plants and energy-storage systems to traditional industrial distribution panels, fuses remain the most reliable and economical means of safeguarding electrical infrastructure against overcurrent and short-circuit faults.

Within the international IEC 60269 standard family, two fuse classes dominate professional selection discussions — gPV and gG.

Although both carry the prefix “g,” meaning “full-range protection,” their applications and electrical behaviors are entirely different.

A gPV fuse is engineered for DC photovoltaic circuits, optimized for the unique challenges of solar energy such as reverse current, long fault durations, and high voltage.

A gG fuse, in contrast, is designed for AC industrial systems, providing comprehensive overload and short-circuit protection for cables, switchgear, and machinery.

This article explores the engineering differences between these two classes, using Aite Fuse’s ATPV-NH2 (gPV) and RT16-2 NH2 (gG) series as examples — both designed and certified to international standards and offering performance comparable to leading brands such as Mersen and Eaton.

2. The Fundamentals of gPV and gG Fuse Design

2.1 The Meaning of “g” in Fuse Classification

The letter “g” in a fuse code indicates full-range protection, meaning the fuse is capable of interrupting both small overload currents and high-energy short circuits. The following letters specify the intended application area:

PV → Photovoltaic (direct-current circuits)

G → General-purpose (alternating-current circuits)

Together, these designations define the fuse’s time-current curve, test requirements, and thermal characteristics under the IEC 60269 framework.

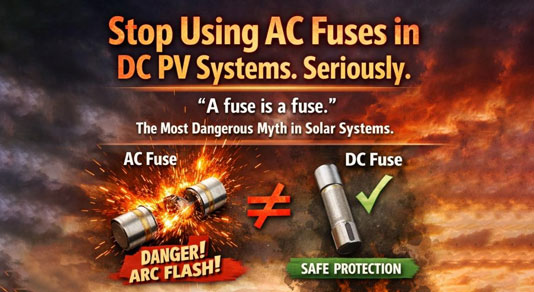

2.2 Why DC and AC Require Different Fuses

Direct current behaves differently from alternating current during a fault. In DC circuits, the current does not naturally cross zero, making arc extinction far more difficult. DC fuses therefore use carefully shaped fuse elements and high-purity quartz sand to interrupt arcs within milliseconds.

AC fuses, by contrast, can take advantage of the natural current zero crossing, allowing a slightly slower response suitable for motor start-up currents and transformer inrush.

3. gPV Fuses for Photovoltaic Protection – Aite Fuse ATPV-NH2 Series

The Aite Fuse ATPV-NH2 1000 VDC Solar PV Fuse Link is a dedicated gPV solution designed for demanding solar environments such as PV array combiners, inverter DC inputs, and re-combiner boxes.

3.1 Product Overview

This NH2-format fuse link features a compact, screw-mountable body that integrates seamlessly with Aite’s ATPV-NH2D 1000 VDC Fuse Base. It is available in current ratings from 63 A to 400 A, meeting the full requirements of IEC 60269-6 and UL 248-19.

3.2 Key Features

Optimized for DC operation: fast-acting element design minimizes energy let-through.

Energy efficiency: low power dissipation reduces system heat and improves yield.

Safety assurance: filled with high-purity quartz sand for rapid arc quenching.

Certified reliability: compliant with TUV, CE, and international PV standards.

Application flexibility: available with striker and microswitch options for remote indication.

•3.3 Typical Applications

•PV array and combiner box protection

•Inverter DC input circuits

•Re-combiner and DC disconnect units

•In-line PV module protection

Engineers appreciate the ATPV-NH2 not only for its proven reliability but also for its compatibility with existing NH mounting systems, making it an ideal choice for both new projects and retrofits.

4. gG Fuses for Industrial AC Protection – Aite Fuse RT16-2 NH2 Series

In industrial environments where alternating current dominates, the Aite Fuse RT16-2 NH2 gG series provides dependable general-purpose protection. Designed for systems up to 690 VAC, it safeguards distribution panels, transformers, and motor control centers against overloads and short circuits.

4.1 Design Characteristics

Each fuse link contains a pure copper or silver element enclosed within a high-strength porcelain body. The cavity is filled with refined quartz sand that extinguishes arcs rapidly at fault interruption. Knife-type contacts ensure secure engagement with the corresponding NH base, promoting reliable conductivity and easy maintenance.

4.2 Typical Applications

Low-voltage switchgear and distribution boards

Transformer secondary protection

Cable and busbar protection

Motor circuits and industrial control equipment

The RT16-2 NH2 conforms to IEC 60269-2 and GB 13539.2, offering the same standardized dimensions and performance characteristics recognized worldwide.

5. gPV vs gG Fuse Comparison

Although both fuse types share similar construction principles, their functions, standards, and electrical behaviors differ. The table below summarizes the essential distinctions that engineers and buyers should understand when selecting a fuse for DC or AC circuits.

|

Feature |

gPV Fuse (Aite Fuse ATPV-NH2 Series) |

gG Fuse (Aite Fuse RT16-2 NH2 Series) |

|

Circuit Type |

DC (Photovoltaic and Energy Storage Systems) |

AC (Industrial Distribution and Motor Control) |

|

Rated Voltage |

Up to 1000 V DC |

Up to 690 V AC |

|

Primary Function |

Fast-acting protection for PV arrays, inverters, and DC inputs |

General protection for cables, switchgear, and electrical equipment |

|

Response Characteristic |

Very fast to clear DC short-circuit and reverse current faults |

Moderate delay to handle overload and motor inrush |

|

Standard Compliance |

IEC 60269-6 / UL 248-19 / TUV / CE |

IEC 60269-2 / GB 13539.2 / CE |

|

Mounting Format |

NH2 PV fuse base (ATPV-NH2D) |

NH2 AC fuse base (RT16-2) |

|

Typical Applications |

Combiner boxes · Inverter DC inputs · Re-combiner units · PV modules |

Distribution panels · Transformers · Industrial control circuits |

|

Arc-Extinguishing Medium |

High-purity quartz sand (optimized for DC arcs) |

High-purity quartz sand (optimized for AC arcs) |

|

Operation Class |

gPV — full-range DC protection |

gG — full-range AC protection |

|

Comparable Brands |

Comparable to Mersen HP10NH and Eaton Bussmann PV series |

Equivalent to Mersen NH gG and Eaton NH industrial fuse links |

5.1 Technical Interpretation

The Aite Fuse ATPV-NH2 gPV fuse demonstrates protection performance comparable to Mersen HP10NH and Eaton Bussmann PV models, recognized worldwide for high-efficiency PV circuit protection.

Similarly, the Aite Fuse RT16-2 NH2 gG follows the same NH structural standards as Mersen NH gG and Eaton NH fuses, ensuring full coordination and interchangeability in AC distribution systems.

Each type serves a specific environment — gPV for solar and DC systems requiring instant fault isolation, gG for industrial AC networks demanding comprehensive overload protection. Both are essential for achieving reliable, compliant electrical design.

6. Engineering Selection Considerations

Choosing between gPV and gG fuses requires more than matching current ratings. Engineers and procurement teams should evaluate:

System Voltage and Type — DC circuits require gPV fuses; AC circuits need gG types.

Fault Characteristics — DC arcs demand faster-acting fuses with sand-filled bodies.

Temperature Derating — Ambient temperature above 40 °C reduces current capacity; apply derating factors.

Mechanical Compatibility — Ensure correct NH size (NH00, NH1, NH2, etc.) and base design.

Certification and Compliance — Select only TUV, CE, or UL-certified fuses for guaranteed safety and insurance validity.

Proper coordination prevents overheating, nuisance tripping, or incomplete protection, ultimately reducing downtime and maintenance costs.

7. Quality and Certification – Aite Fuse Commitment

All Aite Fuse products undergo strict inspection and compliance testing at every production stage.

Key quality principles include:

100% resistance and dimension testing before shipment

Thermal stability and power-dissipation verification under rated load

Compliance with IEC 60269-1/-2/-6, UL 248-1/-19, GB/T 13539, TUV, and CE standards

This ensures that each fuse delivered is ready for installation in PV systems, industrial panels, and OEM equipment worldwide.

Like Mersen and Eaton, Aite Fuse emphasizes precision manufacturing, traceable quality control, and continuous R&D innovation. Its fuses are already used in global solar farms, energy-storage stations, and industrial facilities where reliability and certification matter most.

8. Looking Ahead – The Future of Fuse Technology

With PV system voltages increasing and smart monitoring becoming the norm, fuse technology continues to evolve.

Future directions include:

1500 VDC and beyond protection for utility-scale solar arrays

Integrated sensors for real-time fuse status monitoring

Low-loss materials to improve thermal efficiency

Customized NH2 fuse links optimized for ESS (energy-storage systems) and EV charging

Aite Fuse actively invests in research to develop the next generation of photovoltaic and industrial protection solutions, ensuring customers have access to products that meet tomorrow’s electrical standards today.

9. Conclusion

Both gPV and gG fuses are indispensable in modern electrical protection.

The Aite Fuse’s ATPV-NH2 gPV series provides fast, TUV-certified DC protection for solar and storage applications, while the Aite Fuse RT16-2 NH2 gG series ensures safe and durable AC protection for industrial networks.

By understanding their distinctions and selecting correctly, engineers and buyers can build systems that meet global safety standards, minimize maintenance, and operate efficiently for decades.

With performance comparable to Mersen and Eaton and backed by rigorous certification, Aite Fuse continues to stand as a trusted global partner in reliable, certified, and efficient fuse protection.