What material ensures 1500VDC Photovoltaic Fuse stability

Forget generic fuses; in the high-voltage DC world of utility-scale PV arrays, stability hinges on a core triad: an ultra-pure silver-plated element for predictable melting, a high-purity ceramic body that refuses to carbonize or crack under thermal shock, and a precisely graded arc-quenching filler—typically quartz sand—that chokes an arc within milliseconds. As someone who’s seen fuse bodies literally shatter from inferior materials, I can tell you: the choice here is what stands between a controlled, safe shutdown and a catastrophic fire. Aite’s approach to this material science is what sets the industry benchmark for photovoltaic system protection.

The Staggering Demand for 1500V Solar Fuses

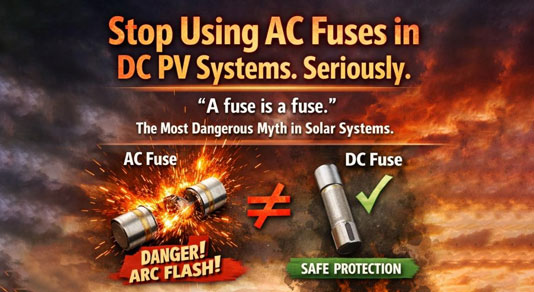

Let’s set the scene. You’re overseeing a 1500V DC PV string. The sun is blazing, current is flowing at peak capacity, and then it happens—an insulation fault, a rodent-chewed cable, a module failure. Suddenly, you have a short-circuit current that can exceed 20kA, all at 1500VDC. Unlike AC, which has a natural current zero point 100 times a second, DC current wants to keep flowing. It creates a sustained, incredibly energetic plasma arc—think of a miniature, persistent lightning bolt inside the fuse. The sole job of your 1500VDC photovoltaic fuse is to interrupt this hellish energy. The materials chosen must simultaneously: withstand massive I²t let-through energy, survive intense internal pressure, quench that arc before it creates a plasma blowtorch, and do it all without rupturing or causing a secondary failure. It’s a material endurance test few components ever face.

Core Component: Silver-plated Copper or Silver Element

The fuse element isn’t just a piece of metal. For a 1500V DC fuse, pure silver or silver-plated materials are non-negotiable. Why? Oxidation. Copper oxidizes over time and under heat, changing its resistance and, critically, its melting point (I²t value). In a PV system expected to last 25+ years, that’s unacceptable. Silver maintains stable characteristics. The plating or pure construction ensures the fuse element melts at the exact, certified point during an overcurrent event, every single time. Aite uses a proprietary alloy and plating process to eliminate performance drift, ensuring your protection coordination remains valid for decades.

Core Component: High-Alumina Ceramic Housing

The tube housing the element cannot be organic or weak. Plastic or fiberglass? Forget it. The thermal and mechanical stresses would cause rupture. The industry standard is a high-alumina ceramic body. This material offers exceptional:

-

Arc Resistance: It won’t carbonize or create conductive tracks on its surface.

-

Mechanical Strength: It contains the explosive pressure of arc interruption.

-

Thermal Shock Resistance: It can go from ambient to several thousand degrees and back without cracking.

Cheap fuses might use lower-grade ceramics. In my audits, I’ve found these with hairline cracks before they even fault—a silent time bomb. Aite’s bodies are rated for multiple high-voltage interruptions, a testament to their structural integrity.

Precision-Graded Quartz Sand Filling

This is the unsung hero, the arc-quenching medium. Not just any sand from the beach. This is chemically pure, moisture-free, and meticulously graded quartz sand. Its grain size, shape, and packing density are calculated with laser precision. When the element melts and the arc forms, the intense heat vitrifies (melts) the surrounding sand. This process absorbs a colossal amount of energy, drastically cools the plasma, and increases the arc’s path resistance, strangling it to extinction. An inconsistent filler leads to incomplete quenching, restrikes, and potentially, the fuse holding the arc in a deadly “closed” state—the opposite of its job.

Beyond the Three Core Components: Key Supporting Materials

Stability isn’t just about the internals.

-

End Caps & Contacts: These must be high-conductivity, corrosion-resistant metals like brass or copper with silver plating. They ensure minimal power loss and heating during normal operation (continuous current rating), which is vital for string fuse efficiency.

-

Arc Voltage Enhancers: Some advanced designs, like those from Aite, incorporate materials within the filler that actively help to elevate the arc voltage during interruption. This technique is crucial for rapidly overcoming the system’s driving DC voltage, forcing the current to zero faster.

-

Hermetic Sealing: The seal that keeps moisture out and filler in is vital. Any ingress of humidity destroys the filler’s quenching ability and can cause premature failure.

A Story from the Field

I recall a site in a coastal, high-humidity region. They’d installed a budget PV fuse on their 1500V inverter combiners. During a routine fault, the fuse didn’t clear cleanly. It arced internally for over a second, superheating the ceramic body until it catastrophically fractured, spraying molten metal and sending a surge back into the combiner box, taking out several surge protection devices (SPDs). The root cause? Post-mortem analysis pointed to two material failures: a slightly porous ceramic tube that had absorbed atmospheric moisture over time, and an inconsistent fuse element alloy. The DC arc found a weakness and exploited it violently. This wasn’t an “act of god”; it was an act of poor material specification.

Why Aite's Material Philosophy Stands Out in Harsh Environments

Every solar environment is brutal: desert heat, freezing alpine cold, salty coastal air, dusty plains. Aite doesn’t believe in a one-fuse-fits-all philosophy. Our customized service starts with understanding your PV system’s specific operating conditions.

-

For High-Altitude, High UV Sites: We specify ceramic compounds and external coatings with enhanced UV stabilization to prevent degradation.

-

For Coastal & Corrosive Atmospheres: Our end caps receive a specialized plating treatment beyond standard silver, and seals are validated for salt mist resistance.

-

For High-Ambient Temperature Farms: We calibrate the I²t characteristics of our elements to account for sustained thermal stress, ensuring the interrupting rating is never compromised.

This scene-aware engineering means the material promise on the datasheet is the material performance in your rack. That’s true photovoltaic system protection.

How to Interpret Certifications and Datasheets

Don’t just glance at the UL 248-19 or IEC 60269-6 listing. Dig deeper into the test reports.

-

Full Interruption Testing at 1500VDC: Ensure the fuse was tested at its full rated voltage, not just a lower extrapolated value. Ask for the test certification.

-

I²t and Peak Let-Through Current Curves: These are direct results of the material science. Lower let-through energy means the materials are quenching the arc faster, protecting your downstream equipment (like the inverter).

-

Endurance & Durability Tests: Look for verification of temperature cycling, humidity exposure, and mechanical shock resistance. These tests prove material stability over time.

Final Connection: Installation and Human Factors

The best materials can be undone by poor handling. I’ve seen a perfectly good 1500VDC photovoltaic fuse installed with a wrench that cracked the ceramic, or inserted into a holder with oxidized contacts that caused hot spots. Always:

-

Use a calibrated torque screwdriver.

-

Ensure combiner busbars are clean and flat.

-

Never install a fuse that has been dropped or shows any sign of damage.

The material’s job is to be stable; our job is to let it do its work.

Conclusion: Stability is a promise of the material itself, not a matter of chance

In the end, the stability of a 1500VDC Photovoltaic Fuse is a direct, non-negotiable function of its material composition. From the predictable fusion of silver to the unyielding strength of high-alumina ceramic, and the life-saving action of quartz sand, each component is a meticulously chosen guardian of your PV array’s safety and ROI. Choosing a fuse based on price alone is a gamble with the highest possible stakes. Choosing one based on transparent, proven, and environment-considered material science—like that engineered into every Aite 1500V solar fuse—is how you build a solar asset that stands the test of time and trouble.

Ready to specify fuses with unshakeable material integrity for your next project?

Visit Aite’s ‘High-Voltage PV Fuse Solutions’ page to access our technical dossiers, certification reports, and connect with our engineering support team for a customized review of your system’s protection needs.