ATTE-800VAC Fused Disconnect Switch: Empowering Professional Upgrades in Industrial and Photovoltaic Power Distribution

In the fields of industrial power distribution and new photovoltaic energy, circuit protection and isolation at the 800VAC voltage level present a core challenge for engineers — requiring compliance with high-voltage safety standards while balancing reliability, maintenance efficiency, and cost. As a specialized manufacturer of low-voltage power distribution protection equipment, AITE offers the HR17, ATR2, and ATR3 series of 800VAC fused disconnect switches and 800VAC photovoltaic fuses. With "in-house manufacturing, scenario-specific adaptation, and end-to-end solutions" as its core strengths, AITE has become the preferred partner for engineers and procurement teams.

I. Brand Expertise: In-House Manufacturing Ensures Quality Foundation

AITE's "professionalism" stems from strict control over the entire product chain. We maintain complete in-house production from key components to finished goods, avoiding quality fluctuations associated with outsourced parts and guaranteeing product reliability.

1. Self-Sufficient Production of Core Components

We specialize in low-voltage fuse protection products, with core product lines covering fused disconnect switches, fuse bases, and PV-specific fuses. Unlike many in the industry who rely on purchased components, every critical part of the HR17, ATR2, and ATR3 series fused disconnect switches and 800VAC PV fuses–from small conductive contacts and insulating housings to large terminals and operating mechanisms–is produced using molds independently developed by AITE. This approach not only ensures part consistency but also enables rapid response to product iteration needs, avoiding supply delays caused by outsourced part shortages.

2. Focused Technological Breakthroughs in 800VAC

With years of dedicated focus in the low-voltage protection segment, AITE has continuously optimized products for the 800VAC voltage level. Our R&D team, targeting demanding applications like industrial heavy-duty and outdoor PV systems, has conducted thousands of simulation tests and field validations. Examples include anti-PID (Potential Induced Degradation) design for PV fuses and selection of impact-resistant insulating materials for fused disconnect switches, ensuring our products meet long-term operational needs in various harsh conditions.

3. Rigorous Quality Control

We have established comprehensive inspection standards spanning from raw material intake to finished product shipment: Raw materials must pass tests for voltage resistance, temperature tolerance, and conductivity; Part dimensional tolerances are strictly controlled within ±0.02mm; Finished products undergo 800VAC rated voltage withstand tests, short-circuit breaking reliability tests, and ≥1000 mechanical endurance cycle tests. All products comply with international IEC and Chinese GB standards, providing engineers with a solid safety foundation for circuit design.

II. Core Products: Precision-Matched to Four Key Applications

The AITE 800VAC product line is designed with an "application-centric" philosophy. Our four main product categories address critical industry needs: space constraints, heavy-duty operations, modular integration, and photovoltaic new energy applications, providing engineers with tailored selection solutions.

1.HR17 800VAC Fused Disconnect Switch: The Preferred Choice for Compact Spaces

Specifically designed for small distribution cabinets and equipment-embedded power units, this model features a vertical installation structure as its core advantage, significantly saving horizontal space within enclosures:

•Integrated Protection & Isolation: Combines fuse protection and isolation functions in a single device, eliminating the need for a separate disconnect switch, thereby simplifying circuit design and reducing component count.

•Easy Maintenance: Compatible with AITE standard fuse bases, allowing fuse replacement without disassembling the entire switch. Engineers can complete maintenance within 3 minutes, minimizing downtime.

•Safe Operation: Features a "tamper-proof" interlock mechanism that prevents the fuse cover from being opened unless the unit is de-energized, eliminating operator shock risk at the design level.

Widely used in machine tool power distribution, compact industrial control units, commercial equipment-embedded power distribution, and other space-constrained applications.

2. ATR2 800VAC Fused Disconnect Switch: A Robust Barrier for Heavy-Duty Applications

Optimized for industrial heavy-duty scenarios, this model focuses on high current-carrying capacity and adaptability to harsh environments, addressing reliability challenges under conditions such as motor starting surges and high-temperature dust:

•Silver-Alloy Contacts: Equipped with silver-alloy conductive contacts featuring contact resistance ≤5mΩ, enabling long-term stable carrying of up to 125A rated current and reducing contact heating losses.

•Reinforced Insulation Housing: Constructed from enhanced PA66 material, with a temperature resistance range of -30°C to 100°C and impact resistance rating of IK08, making it suitable for heavy-duty industrial environments such as metallurgy, chemical plants, and heavy machinery.

•Integrated Fuse & Disconnect Mechanism: Incorporates a linked design between the fuse assembly and the disconnect switch. In the event of a short-circuit fault, fuse operation automatically triggers switch disconnection, preventing sustained arcing and enhancing overall circuit safety.

For procurement teams, its high durability helps reduce equipment replacement frequency and effectively controls long-term operational costs.

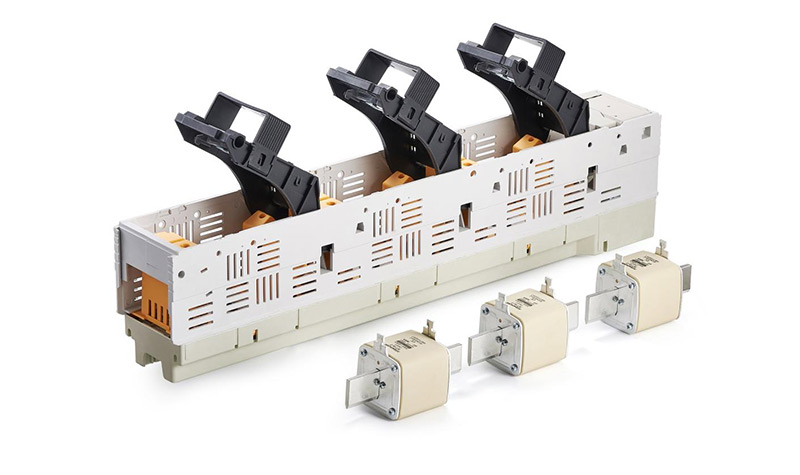

3. ATR3 800VAC Fused Disconnect Switch: An Essential Tool for Complex System Integration

Designed with a modular approach to suit large-scale power distribution systems, this model supports multi-unit parallel configurations, meeting the demands of complex scenarios such as industrial plants and data centers:

•Flexible Parallel Configuration: Allows flexible parallel combination of 2 to 6 units, enabling capacity adjustment according to the power distribution system's current requirements without redesigning the circuit topology.

•Visual Fuse Status Indication: Features a built-in visual indicator window that displays a prominent red signal after fuse operation, allowing engineers to quickly locate fault points without de-energizing the system, thereby enhancing operational efficiency.

•Standardized Connection Interface: Designed with standardized wiring interfaces compatible with most mainstream power distribution equipment, reducing adaptation challenges during system integration.

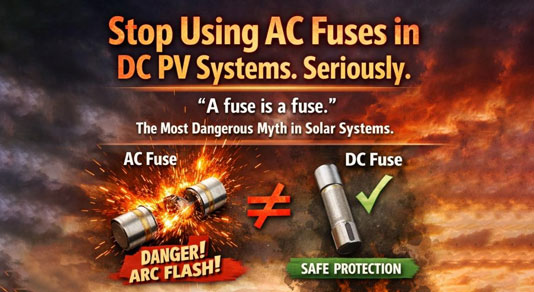

4. 800VAC Photovoltaic Fuse: Dedicated Protection for New Energy Systems

Specially designed for PV combiner boxes and inverters, this fuse addresses key challenges in photovoltaic systems, including outdoor environments, long-term operation, and PID effects:

•Special Ceramic Tube Insulation: Utilizes specialized ceramic housing material that effectively suppresses the impact of Potential Induced Degradation (PID) on fuse performance, ensuring long-term power generation efficiency of PV modules.

•Wide Operating Temperature Range: Functions reliably from -40°C to 85°C with humidity tolerance of 0-95% (non-condensing), capable of withstanding extreme environmental conditions such as daily temperature fluctuations and intense solar exposure in PV power plants.

•Rapid Response Speed: Interrupts faults within ≤10ms, enabling quick circuit disconnection during short-circuit or overload events in inverters and combiner boxes to protect high-value core PV equipment.

•Low Power Consumption Design: Features rated power consumption of ≤0.5W, reducing energy loss in the PV system and indirectly increasing power station generation output.

III. Scenario-Based Solutions: End-to-End Support

AITE goes beyond supplying individual products by building comprehensive, scenario-based solutions around our core 800VAC product line, addressing both the technical requirements of engineers and the efficiency/cost concerns of procurement teams.

1. Industrial Power Distribution Solutions

Focusing on "Safety Protection + Efficient Operation & Maintenance," these solutions adapt to various industrial production environments:

•Main Circuit Protection: Utilizing ATR2 Series Fused Disconnect Switches to handle motor starting inrush currents, while their reinforced enclosures withstand workshop dust and oil contamination.

•Auxiliary Circuit Optimization: Employing HR17 Series switches in compact control units, leveraging their vertical installation design to save space and simplify internal power distribution layout.

•Spare Parts Management: Providing standardized fuse bases and wear parts for the entire product series, reducing the complexity of part matching during maintenance.

2. Photovoltaic Power Plant Solutions

Covering three core areas of PV plants—combiner boxes, inverters, and distribution cabinets—addressing key outdoor distribution challenges:

•Combiner Box Protection: Each PV string is independently protected by an 800VAC Photovoltaic Fuse, preventing a single string fault from affecting the entire system.

•Inverter Isolation: ATR3 Series Fused Disconnect Switches are used at inverter outputs; their modular design supports parallel connection of multiple inverters, and the status indicator function facilitates quick fault diagnosis by maintenance personnel.

•Compliance Assurance: The full product series holds TÜV and UL certifications for the photovoltaic industry, ensuring smooth grid connection acceptance and mitigating compliance risks for procurement teams.

3. Commercial and Civil Power Distribution Solutions

Emphasizing "Space Optimization + Convenient Maintenance," suitable for commercial buildings, data centers, and similar applications:

•Space Saving: Using HR17 Series switches in data center racks, where the vertical installation design saves up to 30% of horizontal space, enabling higher-density equipment deployment.

•Rapid Maintenance: Selecting ATR3 Series switches for commercial building power systems; the status indicator function reduces fault diagnosis time, minimizing commercial losses caused by power interruptions.

•Supply Assurance: Our self-owned manufacturing model ensures stable volume supply. Procurement teams can secure better pricing through long-term cooperation while reducing spare parts inventory pressure.

IV. Why Choose AITE?

For engineers, the core advantage of AITE products lies in their "technical adaptability" — from compact equipment-embedded power distribution to outdoor photovoltaic power stations, from light-load control to industrial heavy-duty applications, you can find precisely matched products without needing to modify designs to accommodate non-specialized equipment. Furthermore, features such as safety lockouts and status visualization significantly reduce maintenance difficulty and safety risks.

For procurement teams, "supply chain reliability" is crucial — in-house mold production ensures stable product quality and avoids batch variations caused by outsourced components. The full product series enables one-stop procurement for both "fuse protection + isolation," reducing the costs associated with managing multiple suppliers. Additionally, the brand's industry technical experience provides selection support, helping avoid potential cost increases arising from product incompatibility.

Amid the wave of industrial upgrading and new energy development, power distribution requirements at the 800VAC voltage level continue to grow. AITE will remain rooted in self-owned manufacturing, continuing to provide engineers with professional technical tools and procurement teams with a stable supply chain through our HR17, ATR2, and ATR3 series fused disconnect switches and 800VAC photovoltaic fuses, serving as your reliable partner in the field of low-voltage power distribution protection.