What is a DC Fuse: DC Fuse Protection Guide

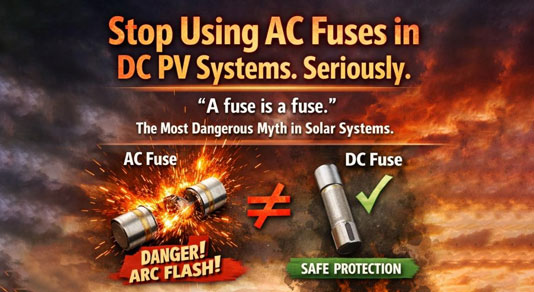

DC fuse are core protection components in DC circuits – they can be considered the "safety valves" of electrical systems. They utilize the thermal melting properties of metal to interrupt fault currents. Unlike AC fuses, which can extinguish arcs using the current's zero-crossing point, DC fuses face a greater challenge. Because DC current is unidirectional and never stops, suppressing the arc is much more difficult. Therefore, DC fuses require special structural designs and materials to ensure reliable current interruption. For buyers, choosing the right DC fuse is not just about checking specifications such as rated voltage or breaking capacity; you also need to match it to the actual application scenario.

The true value of DC fuses lies in preventing problems before they occur. Data from the China Electrical Equipment Industry Association's Fuse Branch shows that 65% of the demand for DC fuses comes from the new energy sector. I can tell you that using the wrong fuse can have catastrophic consequences. I once saw a rooftop photovoltaic project fail because someone used ordinary AC fuses on the DC side of the combiner box. When a short circuit occurred, the fuses failed to extinguish the arc, ultimately leading to the entire combiner box being burned out – a valuable lesson for the buyer.

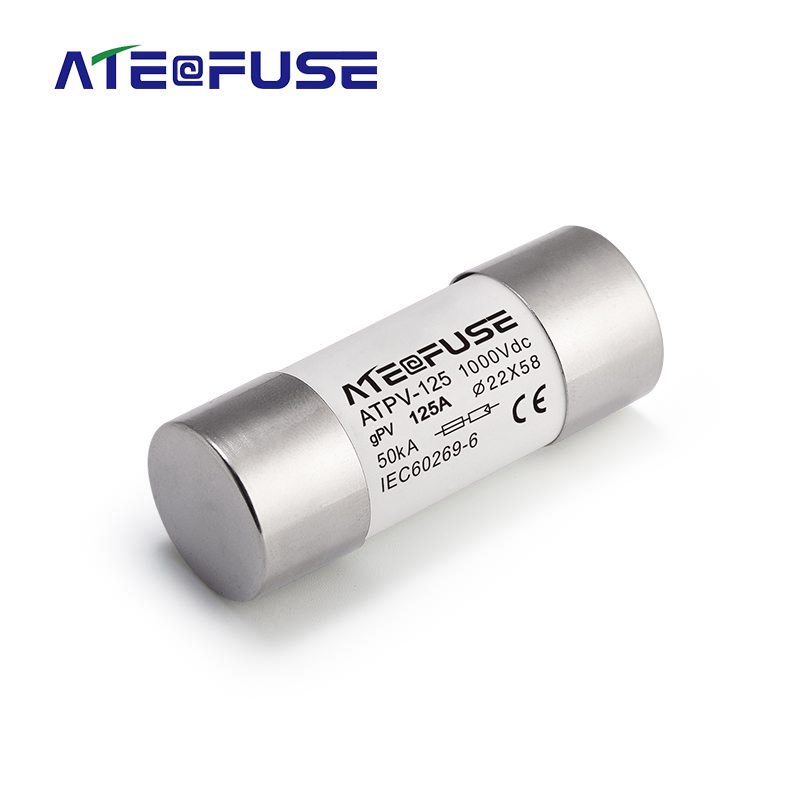

Different application scenarios require different DC fuses, and this is where Aitefuse's customized service excels. Taking large-scale photovoltaic power plants as an example, the standard requires that each string's DC fuse be able to operate at 1.35 times the rated current for 2 hours without failure. Aitefuse's DC fuses, specifically designed for photovoltaic applications, use an optimized silver alloy fuse element structure, controlling the temperature rise to below 40K, which is better than the industry standard of 55K. They can also operate reliably in a temperature range of -40℃ to +85℃, so extreme temperatures are not a problem. Furthermore, in the energy storage sector, over 65% of the market uses 1500V high-voltage systems. Aitefuse's customized fuses have a breaking capacity of 50kA, easily handling the huge short-circuit currents generated by battery packs.

Rail transit is another important market, accounting for 18% of the demand for DC fuses. In this field, vibration resistance and long lifespan are essential. DC fuses in urban rail transit traction systems must withstand continuous mechanical shock during operation. Aitefuse solves this problem with a bolted connection design and reinforced ceramic tubes, ensuring that the fuses remain secure even under severe vibration.

For buyers, choosing a DC fuse is more than just looking at specifications. You need a supplier who understands your pain points. Aitefuse's one-stop service is our strength: we send personnel to the site to inspect your system voltage and fault current, customize time and current characteristic curves to match the components, provide installation services, and continuously monitor product quality after sales. Furthermore, we operate directly without intermediaries, allowing you to obtain high-quality fuses at competitive prices. We also maintain sufficient inventory to ensure on-time delivery, which is crucial for keeping your project on schedule.

In short, a good DC fuse is one whose specifications perfectly match your application scenario. Aitefuse combines advanced automated manufacturing with professional customized services – each fuse not only meets international standards but also satisfies the unique needs of your project. Whether it's new energy, rail transit, or industrial automation, choosing Aitefuse means choosing a reliable guardian for your electrical system.

If you're ready to choose, please click on Aitefuse's contact page!