The Hidden Difference Inside DC fuse Links

From the outside, two DC fuse links may look almost identical. The same cylindrical body, the same metal caps, even the same printed ratings. Yet when procurement managers or engineers compare the options, one often carries a noticeably higher price. Why? The answer lies hidden inside: the material element — copper or silver in DC fuse. And here is where a buyer’s decision can determine not just cost, but also safety, efficiency, and compliance across international projects.

Section 1: Copper in DC fuse Links – The Affordable Standard

Copper has long been the standard choice in DC fuse link elements. It is abundant, relatively inexpensive, and performs adequately in many low-to-medium current applications. For procurement managers handling projects on tight budgets, copper DC fuse links are attractive because they reduce upfront cost.

However, copper comes with limitations. It has higher electrical resistance compared to silver, which means more heat is generated during operation. Over time, this leads to energy loss, accelerated aging, and less predictable fusing performance. In PV systems where efficiency and uptime are paramount, these small inefficiencies can accumulate into noticeable losses.

Section 2: Silver in DC fuse Links – Premium Performance

Silver is the premium material for DC fuse elements. Its electrical conductivity is the highest of all metals, nearly 60% better than copper. This translates into lower power dissipation, faster fusing action, and longer operational stability.

In international renewable energy projects, silver-strip DC fuse links are increasingly the default requirement. They align with IEC60269 and UL248 performance expectations, reduce maintenance interruptions, and ensure higher safety margins under overload or fault conditions.

While silver DC fuse links require higher upfront investment, they deliver measurable savings in downtime reduction, system reliability, and compliance assurance.

Section 3: Cost vs. Value – A Buyer’s Calculation

Procurement is not just about unit price — it is about total cost of ownership.

A case study from a European solar project revealed that although copper DC fuses offered lower initial spending, maintenance downtime increased by 35%. The net result was higher overall project costs compared to silver DC fuses.

This highlights a crucial truth: the cheapest component is not always the most economical choice over the system’s lifetime.

Section 4: Global Compliance Standards

DC fuse element material choice is not just a technical issue — it is also a compliance requirement. International standards such as IEC60269-6 and UL248-19 specify strict performance benchmarks. TUV and CE approvals confirm that the DC fuse can safely operate under photovoltaic system conditions.

In many cases, only silver elements can consistently meet the breaking capacity, arc suppression, and heat dissipation demands required by these standards. For global buyers, ensuring silver-based design is not optional, but mandatory for export-ready systems.

Section 5: Not All Silver DC fuse Strips Are Equal (Case Study)

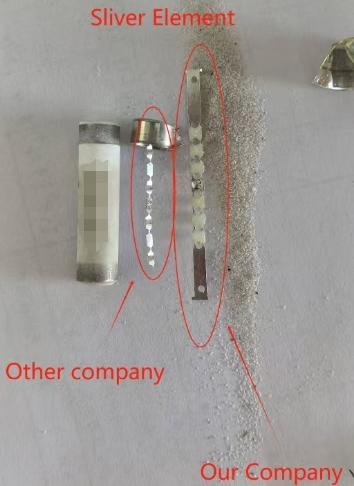

At first glance, every DC fuse link labeled “silver element” may look identical. But once opened, the difference is clear.

In one comparison, DC fuses from two suppliers were tested. Both claimed silver elements. Yet:

Other Company: The silver strip was narrow, irregularly punched, and lacked geometric consistency. This caused uneven heating and premature DC fuse aging.

Our Company: The silver strip was uniform, precision-punched, and optimized for heat dissipation. This ensured predictable breaking performance, lower energy loss, and extended service life.

In field tests, the competitor’s DC fuses triggered inverter trips during peak summer loads, while our company’s silver DC fuses maintained stable operation. This difference translated directly into lower maintenance costs and higher system uptime.

Structured Facts

Topic: Silver Element Quality

Other Supplier: uneven strip, irregular punching

Our Company: precision punching, uniform geometry

Reliability: approx. 20–30% higher

Energy Dissipation: up to 15% lower

Compliance: IEC, UL, TUV met

Impact: reduced trips, higher uptime