The Working Principle of EV Fuses

As electric vehicles (EVs) revolutionize the automotive industry, the safety and reliability of their electrical systems have become paramount. At the heart of this safety framework lies the EV fuse—a deceptively simple component that plays a critical role in protecting high-voltage circuits from damage. Unlike traditional fuses in internal combustion engine vehicles, EV fuses are engineered to handle the unique challenges of high-voltage DC systems, rapid charging currents, and complex power management. This article demystifies the working principle of EV fuses, exploring their design, operation, and safety mechanisms.

The Unique Electrical Landscape of EVs

Before delving into fuse mechanics, it’s essential to understand why EV fuses differ fundamentally from their conventional counterparts:

• High Voltage & Current: Most modern EVs operate at 300–800 volts (some luxury models exceed 1,000V), with charging currents that can reach 500 amps during fast charging. This is 10–20 times the voltage and current of typical 12V automotive systems.

• DC Power Dominance: EV batteries supply direct current (DC), while traditional vehicles rely on alternating current (AC) from alternators. DC circuits pose unique arcing challenges when a fuse interrupts current.

• Complex Power Paths: EVs have multiple power loops: battery to motor, battery to charger, and auxiliary systems. Each loop requires specialized fuse protection.

Core Components of an EV Fuse

An EV fuse is not a generic component; it’s a precision-engineered device with specific features:

1.Fuse Element: Made from alloys like copper, silver, or nickel, designed to melt at precise current thresholds. The element’s shape (flat strip, wire, or thin film) is optimized for rapid heat generation during overcurrent.

2.Arc Quenching Chamber: Critical for DC systems, this chamber uses ceramic, sand, or magnetic fields to extinguish the persistent arc that forms when a DC fuse blows.

3.Housing: Constructed from heat-resistant materials (e.g., ceramic or reinforced plastic) to withstand high temperatures and prevent combustion.

4.Terminals: Heavy-duty connectors that ensure low resistance and secure attachment to high-voltage cables.

How EV Fuses Interrupt Current: The Melting Process

The working principle of an EV fuse revolves around controlled thermal failure:

1.Normal Operation: The fuse element conducts current without overheating. Its resistance is designed to generate minimal heat under rated load.

2.Overcurrent Detection: When current exceeds the fuse’s rating (due to short circuit, overload, or component failure), the fuse element’s resistance causes it to heat up.

3.Melting & Arc Formation: As temperature reaches the alloy’s melting point (typically 200–400°C), the element liquefies and vaporizes, breaking the circuit. In DC systems, this creates a persistent arc due to the lack of natural current zero-crossing.

4.Arc Extinction: The arc quenching chamber kicks in:

• Ceramic Chambers: Absorb arc energy and cool ionized gases.

• Magnetic Fields: Stretch and split the arc, reducing its intensity.

• Sand Filling: Dissipates heat and disrupts the arc path.

5.Complete Interruption: The arc is extinguished, preventing damage to the battery, motor, or charging system.

Key Differences Between EV Fuses and Traditional Fuses

EV fuses incorporate innovations to address high-voltage DC challenges:

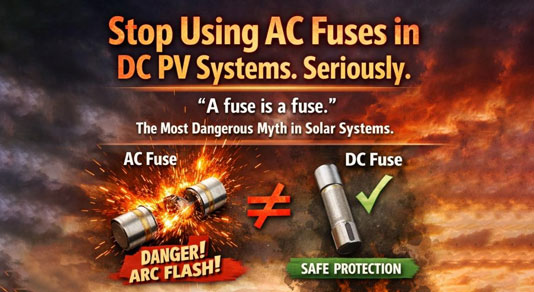

1.Arc Management in DC Systems

• Traditional (AC) Fuses: Rely on natural zero-crossing of AC current to extinguish arcs, requiring simpler designs.

• EV (DC) Fuses: Use active arc quenching (e.g., magnetic blowout coils) to interrupt DC arcs, which can persist for milliseconds—critical in preventing fire risks.

2.Voltage & Current Ratings

• Traditional Fuses: Rated for 12–24V and up to 30A.

• EV Fuses: Rated for 250–1,000V DC and 100–500A, with high breaking capacity (e.g., 10,000A) to handle fault currents.

3.Thermal Response Characteristics

• Traditional Fuses: Designed for slow blow (e.g., to tolerate motor start-up surges).

• EV Fuses: Optimized for fast blow in high-voltage circuits, where even brief overcurrents can damage semiconductors or batteries.

4.Physical Robustness

• Traditional Fuses: Compact, often plug-in designs.

• EV Fuses: Larger, hermetically sealed, and vibration-resistant to withstand EV operational conditions.

EV Fuse Applications: Protecting Critical Systems

EV fuses are strategically placed to safeguard different subsystems:

1.Main Battery Circuit

• Location: Between the battery pack and the powertrain inverter.

• Function: Protects against short circuits in the motor or inverter.

• Example: A 400V EV with a 300A main fuse can interrupt 120,000W of power in milliseconds.

2.Charging Circuit

• Location: In the on-board charger (OBC) or at the charging port.

• Function: Protects against faults during AC-DC conversion or high-power DC fast charging.

• Challenge: Fast charging (e.g., 800V/500A) requires fuses that can handle 400,000W of instantaneous power.

3.Auxiliary Systems

• Location: For 12V auxiliary batteries, HVAC systems, or infotainment.

• Function: Similar to traditional fuses but adapted for EV-specific loads.

Safety Innovations in EV Fuse Design

Modern EV fuses integrate advanced safety features:

1.Intelligent Fuses: Some fuses include embedded sensors that monitor temperature and current, sending alerts before a fault occurs.

2.Thermal Link Technology: Dual-element fuses that combine a fast-blow element for short circuits and a thermal link for overload protection.

3.High Breaking Capacity (HBC) Fuses: Capable of interrupting fault currents up to 100kA, essential for preventing battery fires.

4.Sealed Hermetic Design: Prevents moisture ingress, critical for EVs operating in diverse climates.

Real-World Example: Fuse Operation During a Fault

Imagine an EV with a 400V battery and a 200A main fuse. During a motor short circuit, the current might spike to 1,000A:

1.The fuse element (rated 200A) heats up rapidly due to I²R losses (power = current² × resistance).

2.Within 10–50 milliseconds, the element melts, creating an arc.

3.The arc quenching chamber uses magnetic fields to stretch the arc, increasing its resistance and reducing current.

4.The arc is extinguished within 100 milliseconds, preventing the battery from supplying dangerous levels of energy to the fault.

Future Trends in EV Fuse Technology

As EVs evolve, so will fuse technology:

• Higher Voltage Compatibility: Fuses for 1,000V+ systems in luxury EVs and commercial vehicles.

• Silicon Carbide (SiC) Integration: SiC semiconductors in fuses for faster fault detection and arc suppression.

• Digital Fuse Management: IoT-connected fuses that send diagnostic data to the vehicle’s ECU, enabling predictive maintenance.

• Nano-Composite Materials: Fuse elements with nano-coatings for precise melting points and longer lifespan.

Conclusion

EV fuses are unsung heroes of electric mobility, blending simple physics with advanced engineering to protect high-voltage systems. Their ability to interrupt massive currents while managing destructive arcs is critical for EV safety. As EVs become more powerful and charging networks more robust, the humble fuse will continue to evolve—ensuring that the transition to electric transportation remains safe, reliable, and efficient. Understanding their working principle reveals the intricate balance of science and safety that powers every electric journey.